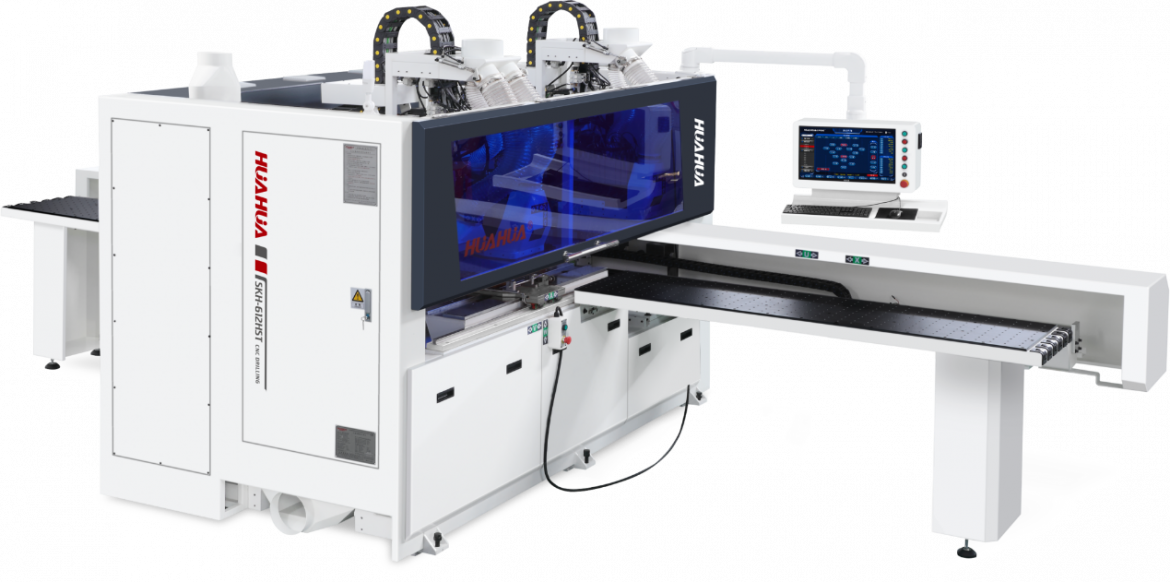

HUAHUA CNC continues to set industry standards with its cutting-edge technology in woodworking machinery. Among its innovations, the SKH-612HST stands out as a high-performance CNC wood drilling machine designed specifically for cabinet production. Equipped with the Taiwan Syntec Control System and Taiwan Syntec servo motor, it offers precision, reliability, and efficiency for large-scale manufacturing needs.

Taiwan Syntec Control System for Maximum Efficiency

The SKH-612HST integrates the Taiwan Syntec control system, which features absolute value control. This means there is no need for homing, and the machine can be used immediately once powered on. Combined with the Taiwan Syntec servo motor, it ensures high stability and superior performance throughout its long service life, making it an ideal investment for woodworking enterprises.

Double Drilling Heads for Faster Processing

One of the most impressive features of the SKH-612HST is its double drilling heads simultaneous processing capability. When the distance between two holes is greater than 85mm, both heads can work at the same time, greatly improving productivity and reducing processing time. This makes it especially suitable for producing bathroom cabinets and kitchen cabinets with consistent precision.

Four Tool Magazines with Automatic Tool Changing

The SKH-612HST is equipped with a straight-line four-tool magazine that allows automatic tool changing. This setup supports continuous and efficient processing of horn handles, embedded handles, laminos, and a variety of invisible parts. The automation not only reduces downtime but also enhances the flexibility of the machine.

Conclusion

As a leading manufacturer, HUAHUA CNC delivers high-quality solutions tailored for modern furniture production. The SKH-612HST CNC wood drilling machine combines innovation, speed, and precision, making it a powerful choice for cabinet manufacturers seeking to improve efficiency and product quality.