In industrial control environments, understanding how a PLC transformer performs under real operating conditions is essential for ensuring stable system behavior. Engineers often evaluate insulation strength, conversion efficiency, and overall component size before integrating these devices into PLC-based automation platforms. Mentech focuses on designing magnetic components that address these factors, offering solutions that fit the practical requirements of signal isolation and power handling. Their development approach allows professionals to examine how a PLC transformer supports reliable operation within compact industrial modules.

Product Characteristics That Support Industrial Requirements

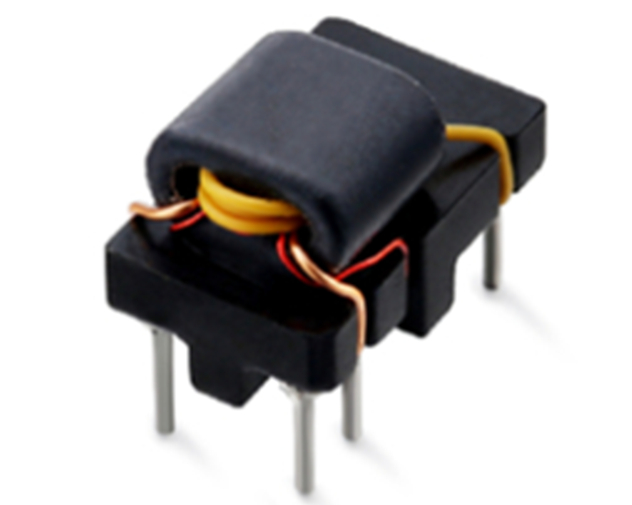

For teams evaluating what makes a PLC transformer suitable for long-term deployment, component structure and electrical resilience are major considerations. Mentech integrates electromagnetic design, reliability testing, and material control into one workflow to help engineers choose components that perform consistently under fluctuating loads. One example is their RFT-002DG model, which uses a DIP mounting structure, supports a 3000V HI-POT rating, and features a 3:4:1 turn ratio within a compact 12.7 × 8.3 mm footprint. These characteristics illustrate how a PLC transformer can achieve insulation strength and signal handling within strict dimensional limits, which is important for automation modules and compact control boards.

How Their Development Approach Aligns With Application Demands

Professionals often ask how a PLC transformer can adapt to different power or communication interfaces without unnecessary redesign. Mentech responds to this need through vertical integration: they operate automated production lines, maintain an internal tooling facility, and support customized development based on application-specific requirements. This structure helps teams—from automotive new-energy engineers to communication-equipment designers—source compatible parts within a stable supply framework. By offering both traditional and newly developed component families, including network magnetics and high-performance inductive components, they provide options that match varied technical priorities.

Conclusion: Practical Magnetic Solutions From Mentech

In conclusion, selecting and applying PLC-related magnetic components requires attention to insulation capability, mechanical format, and long-term reliability. Mentech supports these engineering needs through an extensive product lineup, automated manufacturing capability, and a development system that connects design, tooling, and production. Their service structure emphasizes stable delivery, quality assurance, and practical customization, helping overseas communication-equipment manufacturers, automotive new-energy teams, and procurement engineers source magnetic components efficiently while maintaining consistent technical standards.