Naipu Mining is recognized as a leading trommel screen manufacturer, specializing in the design and production of effective sorting equipment for various industrial applications. With a focus on reliability and efficiency, Naipu Mining’s trommel solutions have become essential tools across industries such as mining and construction.

Versatile Uses of Cylindrical Trommels

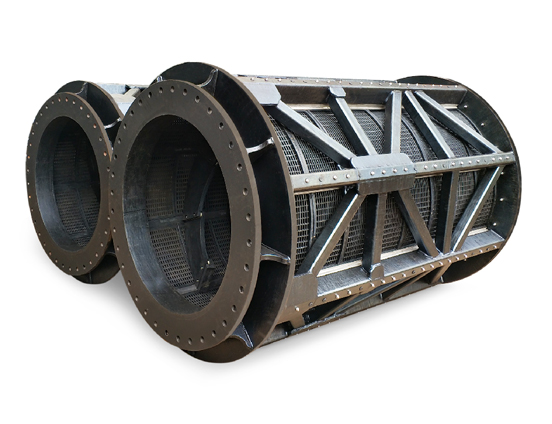

Cylindrical trommels are engineered to provide high efficiency in sorting tasks. These trommels function primarily at mill discharge ends, where they play a crucial role in mass classification and the removal of coarse particles and scats. By employing these trommels, operators can significantly improve hydrocyclone classification efficiency, which, in turn, extends the service life of pumps used in conjunction with the milling process. The straightforward design and reliable operation of these trommel screens ensure that they can be easily integrated into existing systems without extensive modifications.

Enhancing Grinding Processes with Pre-Classifying Trommels

In addition to mass classifying, Naipu Mining’s trommels include pre-classifying self-returning return trommels, particularly useful at the discharge ends of grate mills or AG mills. These specialized trommels effectively control the feed size entering secondary mills, aligning with technological requirements for optimal milling operations. By ensuring that only appropriately sized materials proceed to the next stage, these trommels significantly enhance the efficiency of the entire grinding process. Furthermore, with the capacity to remove broken steel balls, they aid in maintaining the integrity of the milling equipment.

In conclusion, the application of trommels offered by Naipu Mining demonstrates the importance of efficient sorting equipment in industrial processes. As a reputable trommel screen manufacturer, Naipu Mining provides versatile and reliable solutions that optimize operations across various sectors. Deploying trommels not only improves classification efficiency but also contributes to extending the life of other critical equipment in the milling circuit, making them an indispensable asset in modern industrial applications.